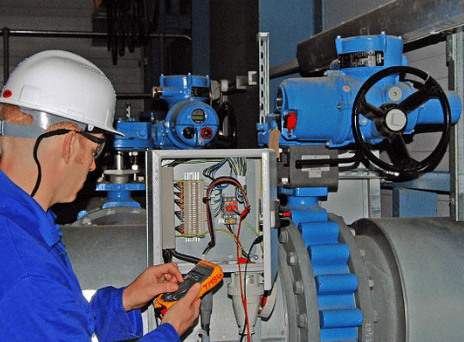

Valves are devices that are used to regulate, control or direct the flow of gases, liquids, or slurries. Industrial valves are those used in industrial rather than domestic settings.

Industrial valves are more robust, as they often have to deal with high-pressure and/or harsh environments. Most utilities would struggle to function without the use of industrial valves.

Types of industrial valve

The majority of industrial valves fall into one of the following categories: linear motion, rotary motion, and self-actuated.

Linear motion valves

There are two types of linear motion valves: axial and rising stem (multi-turn).

Axial valves use either electromagnetic or pneumatic force to move the obstructor along an axis. Examples include angle-seat valves and coaxial valves.

Rising stem valves use a threaded stem that is rotated to move the obstructor. Examples include globe valves, gate valves, pinch valves, and needle valves.

Rotary motion valves

Rotary motion valves use a closure element that rotates to block the flow. In most cases, the rotation is limited to one-quarter turn, with it being completely open at 90 degrees and completely closed at 0 degrees. Examples include ball valves, butterfly valves, and plug valves.

Self-actuated valves

Self-actuated valves use the fluid within the system to position the valve. Examples include relief valves, check valves, safety valves, and steam traps.

If you would like to know more about the applications or types of industrial valves Orseal or another industrial equipment supplier will be able to provide advice and guidance.

Key components of industrial valves

The majority of industrial valves will have the same key components: the valve body/enclosure, the valve bonnet, the actuator, and the valve trim.

The body of the valve is often its largest component and is usually a single piece. The valve bonnet is a casing or cover that provides a tight seal to prevent leaks. The actuator is a crucial part, as it provides the ability to control the flow. The valve trim is the collective term for the replaceable/removable parts, such as the valve seats, discs, bushings, internal springs, and guides.