Copper pipes remain a popular choice because they are reliable, strong, flexible, and corrosion-resistant. They are still used in underwater and gas systems, water distribution systems, and drainage/vent systems.

There are a number of circumstances where copper pipes need to be joined, such as to repair a break or to enable piping to go around a corner/obstruction.

There are a number of popular methods for joining copper pipes. Traditionally the most commonly used are probably welding, soldering, and brazing. However, there are now also some alternatives to these.

Welding

Welding has been around as a method of joining materials for many years. It uses extreme heat to ‘weld’ two parts/materials together, with the join forming as the parts cool down. It is a popular choice for joining copper pipes for several reasons: it forms extremely strong joins, it reduces the chances of leaks, it eliminates the need to use fittings, it can use thinner wall pipe (reducing the cost), it can boost flow, and it is easier to repair and insulate.

Welding can be used to join pipes of the same diameter or pipes of different diameters and is often used for copper pipes but can also be used on PVC pipes using chemical welding.

Modern copper pipe fittings and connectors

In recent years, there has been an increase in the use of specially designed pipe connectors and specialist copper pipe fittings. These are intended to be used where heat-based solutions are not safe or practical.

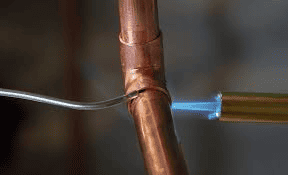

Soldering and brazing

Soldering and brazing are popular methods for joining pipes. Both of these are ‘heat fusion’ methods. Soldering involves the use of a metal alloy (solder) which is heated and used as an adhesive to stick the pipes together, hardening as it cools. Soldering creates permanent bonds and is often used for joining copper water pipes.

Brazing is similar to soldering but it uses higher temperatures and a different ‘filler’ material. Brazed joints are usually slightly stronger than soldered ones.